Auxiliary processing series

+86 18322071688

Hello, everyone in front of the screen. Recently, I have been so busy with my work that I seldom find time to sort out the production method of quick-frozen raw embryo steamed buns. However, many friends in the background have private messages asking about frozen steamed buns. It is said that there is always something wrong with the quick-frozen steamed buns made by our own steamed buns machine -- either the dough crust is cracked or it is not chewy after steaming. It seems that we have to chat with everyone about the ways of this quick-frozen steamed buns. Let's first sort out our train of thought: frozen steamed buns ≠ ordinary steamed buns are frozen directly, and we pay attention to every link from the selection of equipment to the steaming pot. Today, we will reveal all the experience accumulated over the years. The article is a bit long. It is recommended that you collect it before you read it.

one, equipment selection: want to do a good job Must first use

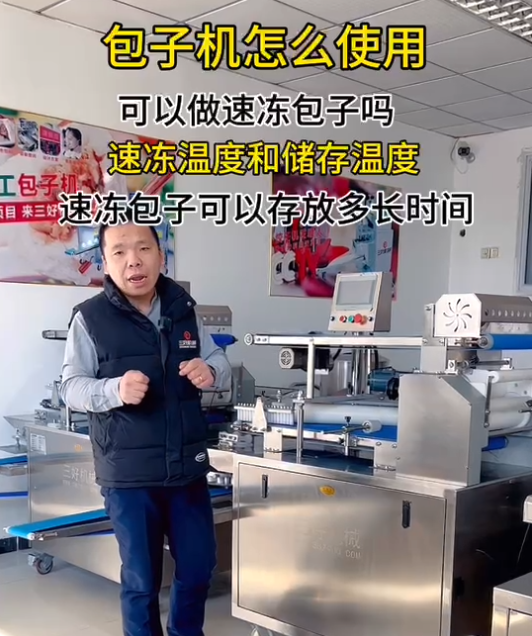

want to make quick-frozen steamed buns, roll bread machine is the basic configuration, that is, Sanhao often said " imitation manual steamed buns machine ", why do we have to use it? There are two keys:

1. Imitation manual rolling technology

the dough pressed by ordinary steamed buns machine is easy to break, while the imitation manual machine adopts spiral rolling, which can retain the integrity of gluten tissue, just like "push, pull, knead" when manual rolling noodles, so that the dough is both elastic and tough, which is the core technology of quick-frozen steamed buns.

2. Filling compatibility Design

filling is too thin? The particles are too big? None of these matters. The hopper and stuffing of Sanhao steamed bun machine are delivered for removable cleaning. No matter it is juicy soup filling or bean paste stuffing with particles, it is easy to handle . Previously, the old iron gave feedback on using ordinary machine master card filling to solve the problem directly.

II, Production process: details determine the success or failure of

1. Dough thickness control

the crust of quick-frozen steamed buns should not be too thin. It is recommended that the crust is thicker than that of ordinary big-fat buns. Through the scale handle on the machine, the thickness of the dough can be accurately controlled, and the measured 6mm thickness is more suitable for quick freezing (thin and easy to break, thick affects taste).

2. Wake up time control

many people will ignore this step. Wrapped steamed buns are recommended to wake up at room temperature for 5 minutes before quick freezing, let the yeast slightly activate, it is easier to expand when steaming, but do not wake up too much, otherwise the facial skin will collapse (there is a prerequisite for this awakening, that is, the level of production is controlled. If the production capacity forms a batch, this step can be omitted, and the details of the operation can be sent in private.

III. Quick freezing: the double game between temperature and time

is the key to the key. Directly affect the taste and shelf life of steamed buns, here is an industry secret: quick-frozen steamed buns to use "deep-frozen" technology, that is,-45 ℃ low-temperature environment, why?

-Fast locking: let the central temperature of steamed buns drop to-18 ℃ within 30 minutes to prevent ice crystals from destroying the cell structure. -Anti-adhesion technique: sprinkle some cornstarch on the steaming plate before quick freezing, or spread a layer of oil paper to prevent the steamed buns from freezing into conjoined twins.

IV. Storage and distribution: the importance of cold chains

1. Long-term storage: frozen steamed buns are stored in-18 ℃ cold storage with a shelf life of up to 6 months. Pay attention to sealed packaging to prevent moisture loss.

2. Short distance delivery: use incubator + ice bag to ensure that the temperature does not exceed-12 ℃. The quality of steamed buns was hardly affected within 2 hours.

V, The steaming time of

frozen steamed buns is 3 minutes longer than that of ordinary steamed buns. For example, ordinary steamed buns are steamed for 8 minutes, while quick-frozen ones are steamed for 11 minutes. Here is a little trick: put the steamed buns in a pot in cold water and time them after being steamed, so that the steamed buns are evenly heated to avoid cooked stuffing.

VI. Pit avoidance Guide: solutions to Common problems

1. Cracked dough: two aspects lead to "not enough quick-freezing temperature, storage problems".

2. Stuffing effluent: root or leaf stem vegetables should be dehydrated.

3. Taste hard: check whether the storage temperature fluctuates, or whether the lid is opened midway during steaming.

in front of the screen, the above is the summary of Sanhao's techniques for making quick-frozen raw embryo steamed buns. what difficulties have you encountered when making quick-frozen steamed buns? Whether it's the dough problem or the filling problem? You can leave a message in the comments area, let's discuss the solution together! If you want to know more about the equipment details or get the stuffing formula, you can also trust me privately to make steamed buns and pay attention to "keeping warm together". Only by learning from each other can we do better and better!

+86 18322071688